Permitting Forms

ORCAA’s staff stands ready to help any resident, business, institution, or agency comply with applicable local, state, and federal air regulations. For assistance, contact a member of the Engineering or Compliance staff.

Additional Resources

The following materials provide guidance on some common questions asked during the permitting process.

- Ecology Guidance:

- EPA’s Support Center for Regulatory Atmospheric Modeling (SCRAM): Air Quality Dispersion Modeling

- A list of nonattainment and maintenance areas in Washington State can be found here.

Businesses should also be aware of the general prohibitions and standards which apply universally to all equipment and activities that generate air emissions. See the Focus Sheet on this topic.

For those looking for self-service help, use the industry-specific tab below to get just the information and forms you’ll need for that category. Find downloadable Source Permitting Forms (PDF Format) may be found here.

Abrasive Blasting

Abrasive Blasting: Do I need a permit?

Abrasive blasting operations generate dust and Toxic Air Pollutants (TAP) emissions and are regulated sources of air pollution. Abrasive blasting operations and equipment typically require approval by ORCAA through a Notice of Construction (NOC) application prior to being established. Examples of when a NOC would be required include:

- Permanent abrasive blasting operations (i.e. not at temporary one-time locations such as cleaning bridges, water towers, buildings, or similar structures).

- Moving an existing abrasive blasting operation to a new location

- Abrasive blasting operations in which the abrasive media is not suspended in water

*Note: If your abrasive blasting project requires the use of a diesel-powered engine greater than 50 HP, please contact ORCAA’s Engineering Department for assistance.

*Some facilities that conduct abrasive blasting also conduct surface coating or painting operations. Please see the Autobody Shops section below or Notice of Construction (NOC) for more information.

To begin the review process, submit the following to ORCAA:

- Form 1

- Form 17

- Project Description

- Site Map

- SEPA documents

- Filing fee

If you have questions, please contact ORCAA’s Engineering Department.

Do I need to be registered?

Abrasive blasting operations that fall under one of the examples listed above are sources of air pollution and are required to register annually with ORCAA.

If you already own or operate a facility that conducts abrasive blasting and are not currently registered, please contact ORCAA’s Engineering Department to determine whether a permit is required and begin the registration process.

Compliance Assistance Tools

Auto Body Shops

Auto Body Spray Coatings: Do I need a permit?

Auto body spray coating operations are stationary sources of air pollution and typically require approval by ORCAA through a Notice of Construction (NOC) application prior to being installed, replaced, relocated or modified. Examples of when a permit would be required include:

- Installing an auto body spray booth or spray coating operation at a new location

- Replacing an existing spray booth with another spray booth

- Moving a spray booth to a new location on the same site

- Reopening an existing autobody shop that has been shut down longer than a year and registration has lapsed.

To receive approval, submit a NOC application to ORCAA including the following:

- Form 1

- Form 8

- Project Description

- Site Map including property lines

- SEPA documents

- Filing fee

Do I need to be registered?

Auto body spray coating operations are stationary sources of air pollution and are required to register annually with ORCAA.

If your auto body spray booth or spray coating operation is not currently registered with ORCAA, please contact ORCAA’s Engineering Department to determine whether a permit is required and begin the registration process.

Compliance Assistance Tools

- Federal Regulations for autobody spray coating operations (external site – opens in new window)

Definition:

“Auto body spray coating operations” means the spray-application of coatings to assembled motor vehicles or mobile equipment. Example activities include spray-applying paint to vehicles and truck bed lining operations. (See Federal Definition)

Boilers & Heaters

Boilers & Heaters: Do I need a permit?

Boilers and heaters that burn fuel are sources of air pollution that typically require approval by ORCAA through a Notice of Construction (NOC) application prior to being constructed or modified. Examples of when a NOC would be required include:

- Installing a new boiler

- Replacing an existing boiler with a functionally identical boiler

- Moving a boiler from one location to another at the same site

- Modifying a boiler to burn a new fuel

- Making physical changes to or changes in the method of operating a boiler that increase emissions

- Adding or replacing boiler control technology like a multi-clone, baghouse or electrostatic precipitator.

- Restarting an existing boiler that has been shut down longer than a year and registration has lapsed.

The following categories of boilers are exempt from air permitting. Boilers:

- Installed prior to December 3, 1969 and have not been modified since this date

- With maximum design heat input rate of 5 MMBtu/hr or less if burning natural gas, propane, or LPG

- With a maximum design heat input rate of 0.5 MMBtu/hr or less if burning waste-derived fuels

- With a maximum design heat input rate of 1 MMBtu/hr or less if burning recycled or used oil per the requirements of RCW 70A.15.4510

- With a maximum design heat input rate of 1 MMBtu/hr or less if burning any other type of fuel with less than or equal to 0.05% sulfur by weight

To receive approval from ORCAA, submit the following:

- Form 1

- Form 11

- Project Description

- Site Map

- SEPA documents

- Filing fee

If you have questions, please contact ORCAA’s Engineering Department.

Do I need to be registered?

Fuel-burning equipment such as boilers are stationary sources of air pollution. Registration of the boiler is required unless it qualifies for one of the exemption categories listed above (based on the design heat input rate and fuel type). If you already own or operate a boiler or heater and are not already registered with ORCAA, please contact ORCAA’s Engineering Department to determine whether a permit is required and begin the registration process.

Compliance Assistance Tools

- Focus on Boiler Tune-ups: Subpart JJJJJJ Requirements. This document details the tune-up requirements for Boilers subject to JJJJJJ

- Combustion Monitoring Worksheet

- Interactive tool to help identify the applicable requirements under 40 CFR Part 63, subpart JJJJJJ (Area Source Boiler NESHAP)

- NESHAP final rule for Industrial, Commercial, and Institutional Boilers (Subpart JJJJJJ)

- Information on how to send in the Initial Notification Form required by the Area Source Boiler MACT (Subpart JJJJJJ)

- Information on how to submit the Electronic Notification of Compliance Status to CEDRI as required by the Area Source Boiler MACT (Subpart JJJJJJ)

- Additional EPA Compliance Tools and Documents for Area Source Boilers

Cannabis Cultivation & Processing

Cannabis Facilities are not required to register with the Olympic Region Clean Air Agency (ORCAA), nor do they need air permits. But these facilities are subject to general nuisance odor prohibitions and associated control requirements, which ORCAA enforces.

ORCAA regulations (Rule 8.5) and Washington’s General Regulations for Air Pollution Sources (WAC 173-400-040(5)) prohibits nuisance odors. Both rules also require the use of recognized good practices and procedures to reduce odors to a reasonable minimum. Violations of these requirements could result in a Notice of Violation (NOV) and penalties.

To avoid nuisance odor issues and possible enforcement, ORCAA recommends Cannabis Facilities implement the following mitigation measures as applicable:

- Maximize Buffers – Grow and production areas and buildings should be situated as far away from neighbors as possible to lessen the likelihood of odor impacts. Outdoor grow operations with repeated nuisance odor violations may need to be either enclosed in approved structures so that odors can be captured and controlled or be relocated far enough away from residences to avoid violations.

- Approved Buildings and Enclosures – All buildings and other structures enclosing Cannabis Facility operations must be permitted by the local city or county agency with authority and must comply with all applicable state and local building codes and standards.

- Air Pollution Control Systems – Any building where growing, drying, or processing takes place should be equipped with an appropriate air pollution control system, designed, and certified by a licensed mechanical engineer. The air pollution control system must be capable of:

- Providing exhaust/ventilation sufficient to meet applicable local, state, and national standards, and maintain a negative pressure within the building whenever odors are generated.

- Exhausting to the outdoor atmosphere above the roof of the building and at a height sufficient to avoid downwash of air emissions on neighboring properties.

- Filtering all exhaust through appropriately sized Granular Activated Carbon (GAC) filtration units or another type of control system demonstrated to be equally effective. Air ionizers may be used if followed by activated GAC systems. Ozone generators are not acceptable as ozone may cause serious health and environmental problems.

- Control System Design Objectives– GAC and other control systems should be designed and sized to:

- Provide high enough exhaust air rates to prevent odors from escaping through other doors, windows, and other openings, thereby avoiding capture and control.

- Effectively control odors during highest odor generation periods (pre-bud and budding periods).

- Provide continuous odor control. For GAC systems, this can be achieved by using dual GAC canisters in series where the secondary canister provides control after breakthrough of the primary while the saturated canister is replaced.

- Maintenance – Odor control systems should be routinely inspected and maintained. If GAC or filter “breakthrough,” clogging, or physical damage is evident, the filter(s) or media should be replaced per manufacturer recommendations. All filters should be tightly seated and operated according to manufacturer recommendations.

- Tight Buildings – Extra measures should be taken to provide air-tight buildings in order to prevent odors from escaping or circumventing the odor control system.

- Waste Materials – Waste materials should be enclosed in air-tight containers to prevent escape of odors prior to removing them from the production building.

- Moisture Control – Cannabis production zone humidity levels and temperatures should be regulated to minimize indoor fungal growth. To effectively regulate humidity, exhaust/ventilation systems should be designed with a dehumidifying system or a controlling interface that monitors airflows and temperature. Generally, humidity below 50-percent minimizes fungal growth.

- Disposal and Waste Practices – Cannabis waste material should be disposed of in a manner that prevents odor generation and emissions.

- Use of Chemicals – Propagation agents, pesticides, fertilizers, and other chemicals should be used, stored, and disposed of according to manufacturer recommendations and in a manner that prevents odors. Safety Data Sheets must be maintained on-site for all chemicals used.

For more information on siting, building, and/or operating a cannabis facility, please contact your local city or county planning/permitting department(s).

Coffee Roaster

Coffee Roaster: Do I need a permit?

Coffee roasters with a design capacity of 10 lbs per batch or greater are sources of air pollution and require approval by ORCAA through a Notice of Construction (NOC) application prior to being installed, replaced, relocated or modified. Examples of when a permit would be required include:

- Installing a coffee roaster with a design capacity of 10 lbs per batch or greater at a new location

- Replacing (even a like-for-like replacement) an existing coffee roaster with another coffee roaster having a design capacity of 10 lbs per batch or greater

- Moving a coffee roaster having a design capacity of 10 lbs per batch or greater to a new location on the same site

- Reopening an existing roasting facility that has been shut down longer than a year and registration has lapsed.

- Installing, adding, replacing, or substantially modifying an afterburner.

To receive approval, submit a NOC application to ORCAA including the following:

- Form 1

- Form 29

- Project Description

- Site Map including property lines

- SEPA documents

- Filing fee

If you have questions, please contact ORCAA’s Engineering Department.

Do I need to be registered?

Coffee roasters with a design capacity of 10 lbs per batch or greater are sources of air pollution and are required to register annually with ORCAA.

If your coffee roaster with a design capacity of 10 lbs per batch or greater is not currently registered with ORCAA, please contact ORCAA’s Engineering Department to determine whether a permit is required and begin the registration process.

Definition

Coffee roasters with a design capacity of 10 lbs per batch or greater” are stationary machines or rotary cylinders used in roasting coffee beans and are capable of roasting 10+ lbs (or 4.5+ kg) of coffee beans during each roast. Examples include but are not limited to: Ambex YM-15, Diedrich IR-5, Diedrich IR-12, Loring S15 Falcon, Loring S70 Peregrine, and Sivetz Coffee, Inc. ¼ Bag.

Crematories

Crematory: Do I need a permit?

Crematories are sources of air pollution and require approval by ORCAA through a Notice of Construction (NOC) application prior to being installed, replaced, relocated or modified. Examples of when a NOC would be required include:

- Installing a crematory at a new location

- Replacing an existing crematory with another crematory

- Moving a crematory to a new location on the same site

- Adding or replacing the afterburner on an existing crematory

- Reopening an existing crematory that has been shut down longer than a year and registration has lapsed.

To receive approval, submit a NOC application to ORCAA including the following:

- Form 1

- Form 36

- Project Description

- Site Map including property lines

- SEPA documents

- Filing fee

If you have questions, please contact ORCAA’s Engineering Department.

Do I need to be registered?

Crematories are stationary sources of air pollution and are required to register annually with ORCAA. If your crematory is not currently registered with ORCAA, please contact ORCAA’s Engineering Department to determine whether a permit is required and begin the registration process.

Compliance Assistance Tools

- Example O&M Plan

“Crematories” are stationary furnaces that are operated to incinerate human or pet remains. Examples include but are not limited to: Advanced Combustion Systems CA0500, All Crematory Company 1701, American A-200 HT, Shenandoah P-25-2GN, and Therm Tec, Inc. SQC-300.

Dry Cleaners

Dry Cleaner: Do I need a permit?

Dry cleaners using Perchloroethylene (aka PCE or PERC) in any amount OR petroleum dry cleaning facilities using a petroleum-based solvent (e.g. DF-2000, EcoSolv, Gen X®) with a total manufacturer’s rated dryer capacity equal to or greater than 84 pounds are sources of air pollution and require approval by ORCAA through a Notice of Construction (NOC) application prior to being installed or replaced. Examples of when a permit would be required include:

- Installing a PERC machine at a new location

- Replacing an existing PERC machine with another PERC machine

- Adding a petroleum dry cleaning machine to an existing operation that brings the facility-wide total manufacturer’s rated dryer capacity equal to or greater than 84 pounds.

- Reopening an existing facility that has been shut down longer than a year and registration has lapsed.

To receive approval, submit a NOC application to ORCAA including the following:

- Form 1

- Form 21 for PERC machines

- Form 21-A for petroleum-based solvent machines

- Form 21-B for alternative solvent machines

- Project Description

- Site Map including property lines

- SEPA documents

- Filing fee

If you have questions, please contact ORCAA’s Engineering Department.

Do I need to be registered?

Dry cleaners using PERC in any amount OR petroleum dry cleaning facilities using a petroleum-based solvent with a total manufacturer’s rated dryer capacity equal to or greater than 84 pounds are sources of air pollution and are required to register annually with ORCAA.

If your dry cleaning operation is not currently registered with ORCAA, please contact ORCAA’s Engineering Department to determine whether a permit is required and begin the registration process.

Compliance Assistance Tools

- Best Management Practices (BMP’s) for dry cleaning facilities exempt from permitting and registration

- Regulations for PERC dry cleaning facilities (external site – opens in new window)

- Federal Regulations for dry cleaning facilities using a petroleum-based solvent (external site – opens in new window)

“Petroleum dry cleaner” means a dry cleaning facility that uses petroleum solvent in a combination of washers, dryers, filters, stills, and settling tanks. (See Federal Definition)

Using a perc detector

- Learn how it should be calibrated. Most require fresh air prior to testing for leaks. It is recommended you turn the detector on outside of your shop. If you turn it on near a leak, it may calibrate incorrectly.

- Learn how it should be calibrated. Most require fresh air prior to testing for leaks. It is recommended you turn the detector on outside of your shop. If you turn it on near a leak, it may calibrate incorrectly.

- Operate your detector according to manufacturer’s instructions.

- Operate your detector according to manufacturer’s instructions.Check for leaks when they are most likely to occur. Check for leaks during the drying cycle since the dry cleaning machine is operating under pressure. Check for leaks around the distillation unit while it is running. You probably won’t find leaks during the wash cycle since perc liquid is being agitated in the drum and the condenser isn’t running.

- Check for leaks when they are most likely to occur. Check for leaks during the drying cycle since the dry cleaning machine is operating under pressure. Check for leaks around the distillation unit while it is running. You probably won’t find leaks during the wash cycle since perc liquid is being agitated in the drum and the condenser isn’t running.

- Place the tip of the detector within one to two inches of the area being checked. Move it slowly back and forth before moving to the next location.

- Place the tip of the detector within one to two inches of the area being checked. Move it slowly back and forth before moving to the next location.

- If the detector beeps rapidly, you may have a leak. Go back to the area where you first detected the beeps. You want to find the exact spot where the detector reliably beeps so you know the precise part or location of the leak.

- If the detector beeps rapidly, you may have a leak. Go back to the area where you first detected the beeps. You want to find the exact spot where the detector reliably beeps so you know the precise part or location of the leak.

- If the instrument detects a perc vapor leak or is set off, make sure to air it out before continuing the inspection; otherwise, you may have incorrect results.

Emergency Engines

Emergency Engines: Do I need a permit?

Stationary internal combustion engines with a rated capacity of 500 hp or greater and used for standby emergency power are sources of air pollution and require approval by ORCAA through a Notice of Construction (NOC) application prior to being installed, replaced, relocated or modified. Examples of when a permit would be required are:

- Installing an emergency engine at a new location

- Replacing an existing emergency engine with another emergency engine

- Moving an emergency engine to a new location on the same site

- Restarting an existing emergency engine that has been shut down longer than a year and registration has lapsed.

To receive approval, submit a NOC application to ORCAA including the following:

- Form 1

- Form 18

- Project Description

- Site Map including property lines

- SEPA documents

- Filing fee

If you have questions, please contact ORCAA’s Engineering Department.

Do I need to be registered?

Stationary internal combustion engines with a rated capacity of 500 hp or greater and used for standby emergency power are sources of air pollution and are required to register annually with ORCAA.

If your emergency engine is not currently registered with ORCAA, please contact ORCAA’s Engineering Department to determine whether a permit is required and begin the registration process.

Compliance Assistance Tools

- Federal Regulations for Stationary Engines (external site)

“Emergency engines” are stationary internal combustion engines that are operated to provide electrical power or mechanical work during an emergency situation. Examples include engines used to produce power for critical networks or equipment when electric power from the normal power source is interrupted or engines used to pump water in the case of fire or flood, etc. (See Federal Definition)

Gas Stations

Gas Station: Do I need a permit?

Gasoline dispensing facilities are sources of air pollution that typically require approval by ORCAA through a Notice of Construction (NOC) application prior to being constructed or modified. Examples of when a permit would be required include:

- Constructing a new gas station with a facility-wide gasoline storage capacity of 10,000 gallons or greater.

- Adding or replacing a gasoline storage tank with a capacity of 2,000 gallons or more and located at a gasoline dispensing facility with a cumulative storage capacity of 10,000 gallons or more.

- Removing a Stage 2 system.

- Replacing or substantially modifying vapor control technology (contact ORCAA’s Engineering Department for a case specific determination).

- Re-opening a station that has been shut down longer than a year and registration has lapsed (contact ORCAA’s Engineering Department for a case specific determination).

To receive approval from ORCAA, submit the following:

- Form 1

- Form 16

- Project Description

- Site Map

- SEPA documents

- Filing fee

As of August 17, 2019, ORCAA will accept a Notice of Intent (NOI) in lieu of an NOC for certain qualifying projects. Complete NOI applications must be submitted 15 days prior to commencing construction. To qualify for the NOI, all of the criteria must be met:

- The proposed vapor recovery equipment must be in accordance with the current California Air Resources Board (CARB) Executive Orders at the time of filing the notification;

- The gasoline dispensing facility cannot be part of a stationary source subject to the Air Operating Program;

- The gasoline dispensing facility cannot be subject to any of the Stage II requirements in WAC 173-491-040(5); and,

- The project cannot involve the removal of a Stage II vapor recovery system.

If you cannot meet the above criteria for a NOI, the project will need to be reviewed through our Notice of Construction process.

If you have questions, please contact ORCAA’s Engineering Department.

*Note: As of July 1, 2016, fees are adjusted each year on July 1. If you are modifying an existing gas station, you may qualify for an adjustment to your filing fee. Please contact ORCAA’s Engineering Department. for a determination.

Do I need to be registered?

Gasoline dispensing facilities are sources of air pollution and are required to register annually with ORCAA.

If you already own or operate a gasoline dispensing facility and are not currently registered, please contact ORCAA’s Engineering Department to determine whether a permit is required and begin the registration process.

Compliance Assistance Tools

- Self inspection Guide

- Self-Inspection Form – Tanks

- Self Inspection Form – Pumps, Vacuum Assist

- Self Inspection Form – Pumps, Vapor-balance

- Gas Dispensing Fact Sheet

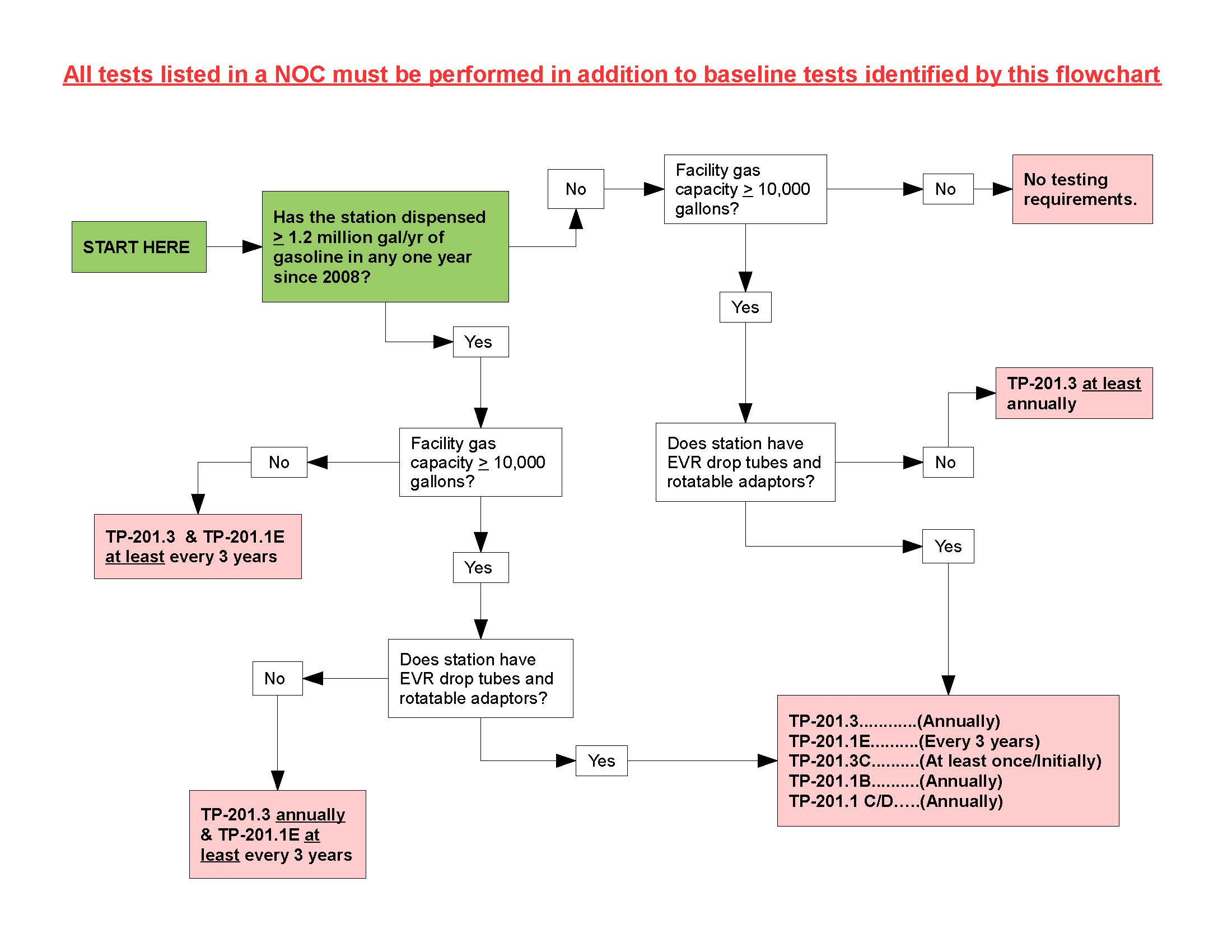

- Testing Requirement Flowchart

- Federal Regulations for Gasoline Dispensing Facilities (external site)

- Map of all ORCAA Gasoline Dispensing Facilities, with pertinent testing requirements included for each source

Rock Crushers

Rock Crushing: Do I need a permit?

Rock crushing plants are regulated as stationary sources of particulate matter air pollution and subject to both federal and Washington standards. (Rock crushing plants emit particulate matter air pollution and have the potential to emit Toxic Air Pollutants (TAP) such as, but not limited, to crystalline silica, lead, and asbestos.) Fixed rock crushing plants (those that are not portable) with capacities greater than 25 tons per hour and portable rock crushing plants with capacities greater than 150 tons per hour, and that remain no longer than 12-months at any location, require approval by ORCAA through a Notice of Construction (NOC) application before they are established at any site. Once approved through a NOC, portable rock crushing plants may relocate provided a Notice of Intent to Operate (NOI) is filed with ORCAA at least 15-days prior to relocating the plant.

The following actions involving rock crushing operations trigger an air permit through ORCAA:

- Establishing a rock crushing plant in ORCAA’s jurisdiction for the first time (NOC required)

- Moving a fixed rock crushing plant to a new location (NOC required)

- Relocating a portable rock crushing plant (NOI required)

- Replacing or adding crushers (NOC required)

- Replacing or adding stationary engines greater than 50 bhp (NOI or NOC required)

- Restarting an existing rock crushing plant that has been shut down longer than a year and registration has lapsed.

General Rock Crusher Approval:

Certain rock crushing plants may be approved under ORCAA’s General Rock Crusher Approval, which pre-approves certain equipment changes (like adding an additional crusher) and relocations that would otherwise re-trigger air permitting. The key prerequisites for approval under ORCAA’s General Rock Crusher Approval are:

- The plant must register with ORCAA annually;

- Production must be limited to no more than 5,400 tons per day (annual average) and 1,000,000 tons per year;

- Cumulative capacity of stationary nonroad engines must not exceed 2000 (bhp);

- The rock crusher must operate at sites with existing approval to conduct rock crushing (like registered sand and gravel mining sites); and,

- The rock crusher must be located a minimum of 150 feet from any property line and 500 feet from any residence, occupied commercial building, school, hospital, nursing home or other sensitive receptor.

Air Permit Application Process:

Approval by ORCAA is required prior to initiating any action that triggers an air permit. To receive approval, submit the appropriate application forms, fees and include the materials specified in the table below. The option for approval under ORCAA’s General Rock Crusher Approval may be requested in conjunction with either permitting action by selecting this option on Form 24 and affirming the minimum qualifying criteria.

| Air Permit: | NOC Application | NOI Application |

| Required for: | • Establishing a rock crushing plant (fixed or portable) in ORCAA’s jurisdiction for the first time • Moving a fixed rock crushing plant to a new location • Replacing or adding crushers to a fixed or portable plant • Replacing or adding stationary engines greater than 50 bhp | • Relocating a portable rock crushing plant (NOI required) • Replacing or adding crushers (NOC required) • Replacing or adding stationary, nonroad engines greater than 50 bhp |

| Review time: | 15 – 90 days | 15 days |

| Required Application: | 1. NOC Form 1 2. Form 24 3. NOC Filing fee | 1. NOI Form 1C 2. Form 24 3. NOI Filing Fees |

4. Additional information required for all applications:

- Plant diagram showing the sequence of all crushers, screens, conveyors and location of water spray.

- Site Map showing location of plant, property lines and major haul roads.

- SEPA documents

For more information on the permitting process and the items required above, please contact ORCAA’s Engineering Department.

Do I need to be registered?

Fixed rock crushing plants, and portable rock crushing plants approved under ORCAA’s General Rock Crusher Approval, are required to register with ORCAA annually. If your rock crushing plant is not currently registered with ORCAA, please contact ORCAA’s Engineering Department to determine whether a permit is required and begin the registration process.

Compliance Assistance Tools

- ORCAA’s General Rock Crusher Approval & Technical Support Document

- Federal Regulations for fixed and portable rock crushing plants (external link – opens in new window)

Soil Remediation

Soil Remediation: Do I need a permit?

Soil and water remediation cleanup projects often result in the emission of dissolved hydrocarbons and Toxic Air Pollutants (TAP), and typically require approval by ORCAA through a Notice of Construction (NOC) application prior to installing equipment used for:

- Aeration

- Air Stripping

- Air Sparging

- Soil Vapor Extraction

- Thermal oxidation, or catalytic oxidation

An NOC is required for the following cleanup projects:

- Installing a new cleanup system

- Relocating an existing cleanup system

- Removing or modifying air pollution control on an existing system

See this list for a summary of the cleanup methods listed above and call ORCAA’s Engineering Staff if you have any questions.

To receive approval from ORCAA, submit the following:

- Form 1

- Form 15

- Project Description

- Site Map

- SEPA documents

- Filing fee

If you have questions, please contact ORCAA’s Engineering Department.

Do I need to be registered?

Soil and water remediation projects are sources of air pollution and are required to register annually with ORCAA during the cleanup process. If you already manage or operate a soil or water remediation project and are not currently registered, please contact ORCAA’s Engineering Department to determine whether a permit is required and begin the registration process.

Compliance Assistance Tools

- EPA: A Citizen’s Guide to Soil Vapor Extraction and Air Sparging (external link – opens in new window)

- EPA: Soil Vapor Extraction (SVE) Enhancement Technology Resource Guide (external link – opens in new window)